Oil and Gas Well Drilling and Servicing eTool

Oil and Gas Well Drilling and Servicing » Glossary of Terms - S

† This is an abridged version of the Dictionary of Petroleum Terms provided by Petex and the University of Texas Austin. © Petex 2001

safety clamp

n: a clamp placed tightly around a drill collar that is suspended in the rotary table by drill collar slips.

safety joint

n: an accessory to a fishing tool, placed above it. If the tool cannot be disengaged from the fish, the safety joint permits easy disengagement of the string of pipe above the safety joint. Thus, part of the safety joint and the tool attached to the fish remain in the hole and become part of the fish.

safety slide

n: a device normally mounted near the monkey board to afford the derrickhand a means of quick exit to the surface in case of emergency. It is usually affixed to a wireline, one end of which is attached to the derrick or mast and the other end to the surface. To exit by the safety slide, the derrickhand grasps a handle on it and rides it down to the ground. Also called a Geronimo.

salinity log

n: a special nuclear well log that produces an estimate of the relative amounts of oil, gas, or salt water in a formation. This log is electronically adjusted to reflect gamma ray emissions resulting from the collision of neutrons with chlorine atoms in the formations.

samples

n pl: 1. the well cuttings obtained at designated footage intervals during drilling. From an examination of these cuttings, the geologist determines the type of rock and formations being drilled and estimates oil and gas content. 2. small quantities of well fluids obtained for analysis.

sand

n: 1. an abrasive material composed of small quartz grains formed from the disintegration of pre-existing rocks.

sand consolidation

n: any one of several methods by which the loose, unconsolidated grains of a producing formation are made to adhere to prevent a well from producing sand but permit it to produce oil and gas.

sand control

n: any method by which large amounts of sand in a sandy formation are prevented from entering the wellbore. Sand in the wellbore can cause plugging and premature wear of well equipment.

sandfrac

n: method of fracturing subsurface rock formations by injecting fluid and sand under high pressure to increase permeability. Fractures are kept open by the grains of sand.

sandline

n: a wireline used on drilling rigs and well-servicing rigs to operate a swab or bailer, to retrieve cores or to run logging devices. It is usually 9/16 of an inch (14 millimeters) in diameter and several thousand feet or meters long.

sandstone

n: a sedimentary rock composed of individual mineral grains of rock fragments between 0.06 and 2 millimeters (0.002 and 0.079 inches) in diameter and cemented together by silica, calcite, iron oxide, and so forth.

saver sub

n: an expendable substitute device made up in the drill stem to absorb much of the wear between the frequently broken joints (such as between the kelly or top drive and the drill pipe).

scale

n: 1. a mineral deposit (for example, calcium carbonate) that precipitates out of water and adheres to the inside of pipes, heaters, and other equipment. 2. an ordered set of gauge marks together with their defining figures, words, or symbols with relation to which position of the index is observed when reading an instrument.

scraper

n: any device that is used to remove deposits (such as scale or paraffin) from tubing, casing, rods, flow lines, or pipelines.

scratcher

n: a device that is fastened to the outside of casing to remove mud cake from the wall of a hole to condition the hole for cementing.

screening effect

n: the tendency of proppants to separate from fracture fluid when the speed, or velocity, of the fluid is low.

secondary recovery

n: 1. the use of water-flooding or gas injection to maintain formation pressure during primary production and to reduce the rate of decline of the original reservoir drive. 2. water-flooding of a depleted reservoir. 3. the first improved recovery method of any type applied to a reservoir to produce oil not recoverable by primary recovery methods. See primary recovery.

self-potential (SP)

n: see spontaneous potential.

self-propelled unit

n: see carrier rig.

service company

n: a company that provides a specialized service, such as a well-logging service or a directional drilling service.

service rig

n: see production rig.

service well

n: 1. a nonproducing well used for injecting liquid or gas into the reservoir for enhanced recovery. 2. a saltwater disposal well or a water supply well.

set back

v: to place stands of drill pipe and drill collars in a vertical position to one side of the rotary table in the derrick or mast of a drilling or workover rig. Compare lay down pipe.

set casing

v: to run and cement casing at a certain depth in the wellbore. Sometimes called set pipe.

set pipe

v: see set casing.

set up

v: to harden (as cement).

shaker

n: shortened form of shale shaker. See shale shaker.

shale

n: a fine-grained sedimentary rock composed mostly of consolidated clay or mud. Shale is the most frequently occurring sedimentary rock.

shale shaker

n: a vibrating screen used to remove cuttings from the circulating fluid in rotary drilling operations. Also called a shaker.

shear ram

n: the component in a blowout preventer that cuts, or shears, through drill pipe and forms a seal against well pressure.

shear ram preventer

n: a blowout preventer that uses shear rams as closing elements.

sheave

(pronounced "shiv") n: 1. a grooved pulley. 2. support wheel over which tape, wire, or cable rides.

shoulder

n: 1. the flat portion machined on the base of the bit shank that meets the shoulder of the drill collar and serves to form a pressure-tight seal between the bit and the drill collar. 2. the portion of the box end or the pin end of a tool joint; the two shoulders meet when the tool joint is connected and form a pressure-tight seal.

shut in

v: 1. to close the valves on a well so that it stops producing. 2. to close in a well in which a kick has occurred.

shut-in bottomhole pressure (SIBHP)

n: the pressure at the bottom of a well when the surface valves on the well are completely closed. It is caused by formation fluids at the bottom of the well.

sidetrack

v: to use a whipstock, turbodrill, or other mud motor to drill around the original planned path of the well.

single

n: a joint of drill pipe. Compare double.

single-pole rig

n: a well-servicing unit whose mast consists of but one steel tube, usually about 65 feet (19.8 meters) long.

sinker bar

n: a heavy weight or bar placed on or near a lightweight wireline tool. The bar provides weight so that the tool will lower properly into the well.

slack off

v: to lower a load or ease up on a line. A driller will slack off on the brake to put additional weight on the bit.

sleeve

n: a tubular part designed to fit over another part.

slick line

n: see wireline.

slip-and-cutoff program

n: a procedure to ensure that the drilling line wears evenly throughout its life. After a specified number of ton-miles (megajoules) of use, the line is slipped-for example, the traveling block is suspended in the derrick or propped on the rig floor so that it cannot move, the deadline anchor bolts are loosened, and the drilling line is spooled onto the drawworks drum. Enough line is slipped to change the major points of wear on the line, such as where it passes through the sheaves. To prevent excess line from accumulating on the drawworks drum, the worn line is cut off and discarded.

slip bowl

n: a device in a rotary table or other tool into which tubing or drill pipe it is wrapped with specially shaped wire that is designed to prevent the entry of loose sand into the well as it is produced. It is also often used with a gravel pack.

slips

n: wedge-shaped pieces of metal with teeth or other gripping elements that are used to prevent pipe from slipping down into the hole. Rotary slips fit around the drill pipe and wedge against the master bushing to support the pipe. Power slips are pneumatically or hydraulically actuated devices. Packers and other down hole equipment are secured in position by slips that engage the pipe by action directed at the surface.

sloughing hole

n: a condition wherein shale that has absorbed water from the drilling fluid expands, sloughs off, and falls downhole. A sloughing hole can jam the drill string and block circulation.

slug

n: a quantity of fluid injected into a reservoir to accomplish a specific purpose, such as chemical displacement of oil.

slurry

n: 1. in drilling, a plastic mixture of cement and water that is pumped into a well to harden. There it supports the casing and provides a seal in the wellbore to prevent migration of underground fluids. 2. a mixture in which solids are suspended in a liquid.

solution gas

n: lighter hydrocarbons that exist as a liquid under reservoir conditions but that effervesce as gas when pressure is released during production.

sonic log

n: a type of acoustic log that records the travel time of sounds through objects, cement, or formation rocks. Often used to determine whether voids exist in the cement behind the casing in a wellbore.

sour corrosion

n: embrittlement and subsequent wearing away of metal caused by contact of the metal with hydrogen sulfide.

sour crude oil

n: oil containing hydrogen sulfide or another acid gas.

SP

abbr: spontaneous potential or self potential.

spear

n: a fishing tool used to retrieve pipe lost in a well. The spear is lowered down the hole and into the pipe being fished.

speed reducer

n: a set of gears installed between a prime mover and the equipment it drives to reduce the running speed. For example, on a beam pumping unit, the engine may run at a speed of 600 revolutions per minute, but the pumping unit it drives may need to operate at 20 strokes per minute. The speed reducer makes it possible to obtain the correct pump speed.

spent

adj: descriptive of a substance whose strength or merit has been exhausted in a process. For example, after a well has been acidized, any acid that remains in the well is said to be a spent acid because its strength has been used up in the acidizing process.

spinning cathead

n: see makeup cathead, spinning chain.

spinning chain

n: a relatively short length of chain attached to the tong pull chain on the manual tongs used to make up drill pipe. The spinning chain is attached to the pull chain so that a crew member can wrap the spinning chain several times around the tool joint box of a joint of drill pipe suspended in the rotary table. After crew members stab the pin of another tool joint into the box end, one of them then grasps the end of the spinning chain and with a rapid upward motion of the wrist "throws the spinning chain"-that is, causes it to unwrap from the box and coil upward onto the body of the joint stabbed into the box. The driller then actuates the makeup cathead to pull the chain off of the pipe body, which causes the pipe to spin and thus the pin threads to spin into the box.

spinning wrench

n: air-powered or hydraulically powered wrench used to spin drill pipe in making or breaking connections.

spontaneous potential (SP)

n: one of the natural electrical characteristics exhibited by a formation as measured by a logging tool lowered into the wellbore. Also called self-potential or SP.

spontaneous potential (SP) curve

n: a measurement of the electrical currents that occur in the wellbore when fluids of different salinities are in contact. The SP curve is usually recorded in holes drilled with freshwater-base drilling fluids. It is one of the curves on an electric well log. Also called self-potential curve.

spontaneous potential (SP) log

n: a record of a spontaneous potential curve.

spool

n: the drawworks drum. Also a casing head or drilling spool. v: to wind around a drum.

spot

v: to pump a designated quantity of a substance (such as acid or cement) into a specific interval in the well. For example, 10 barrels (1,590 litres) of diesel oil may be spotted around an area in the hole in which drill collars are stuck against the wall of the hole in an effort to free the collars.

spud

v: 1. to begin drilling a well; such as, to spud in. 2. to force a wireline tool or tubing down the hole by using a reciprocating motion.

spud in

v: to begin drilling; to start the hole.

spud mud

n: the fluid used when drilling starts at the surface, often a thick bentonite-lime slurry.

split master bushing

n: a master bushing that is made in two pieces.

squeeze

n: 1. a cementing operation in which cement is pumped behind the casing under high pressure to recement channeled areas or to block off an uncemented zone.

squeeze cementing

n: the forcing of cement slurry by pressure to specified points in a well to cause seals at the points of squeeze. It is a secondary cementing method that is used to isolate a producing formation, seal off water, repair casing leaks, and so forth. Compare plug-back cementing.

squeeze job

n: a remedial activity whereby a cement slurry is pumped into open perforations, split casing, or a fractured formation, to effect a blockage.

squeeze packer

n: a downhole permanent, or drillable, packer that is set by lowering some of the weight of the tubing string onto the packer. The weight expands the packer's sealing element to prevent flow between the tubing string and the casing below the packer.

squeeze point

n: the depth in a wellbore at which cement is to be squeezed.

squeeze tool

n: a special retrievable packer set at a particular depth in the wellbore during a squeeze cementing job. See also squeeze cementing.

stabilizer

n: 1. a tool placed on a drill collar near the bit that is used, depending on where it is placed, either to maintain a particular hole angle or to change the angle by controlling the location of the contact point between the hole and the collars.

stack

n: 1. a vertical arrangement of blowout prevention equipment. Also called preventer stack. See blowout preventer. 2. the vertical chimney-like installation that is the waste disposal system for unwanted vapor such as flue gases or tail-gas streams.

stack a rig

v: to store a drilling rig on completion of a job when the rig is to be withdrawn from operation for a time.

stairways

n: stairs leading from one level to another.

stand

n: the connected joints of pipe racked in the derrick or mast when making a trip. On a rig, the usual stand is about 90 feet (about 27 meters) long (three lengths of drill pipe screwed together).

standard derrick

n: a derrick that is built piece by piece at the drilling location, as opposed to a jackknife mast, which is preassembled. Compare mast.

standing valve

n: a fixed ball-and-seat valve at the lower end of the working barrel of a sucker rod pump. The standing valve and its cage do not move, as does the traveling valve. Compare traveling valve.

standpipe

n: a vertical pipe rising along the side of the derrick or mast, which joins the discharge line leading from the mud pump to the rotary hose and through which mud is pumped going into the hole.

steam flooding

n: a thermal recovery method in which steam is injected into a reservoir through injection wells and driven toward production wells. The steam reduces the viscosity of crude oil, causing it to flow more freely. The heat vaporizes lighter hydrocarbons; as they move ahead of the steam, they cool and condense into liquids that dissolve and displace crude oil. The steam provides additional gas drive. This method is also used to recover viscous oils. Also called continuous steam injection or steam drive. Compare thermal recovery.

steel-tooth bit

n: a roller cone bit in which the surface of each cone is made up of rows of steel teeth. Also called a milled bit, although some steel teeth are forged.

stimulation

n: the action of attempting to improve and enhance a well's performance by the application of horsepower using pumping equipment, placing sand in artificially created fractures in rock, or using chemicals such as acid to dissolve the soluble portion of the rock.

straight hole

n: a hole that is drilled vertically. The total hole angle is restricted, and the hole does not change direction rapidly.

string

n: the entire length of casing, tubing, sucker rods, or drill pipe run into a hole.

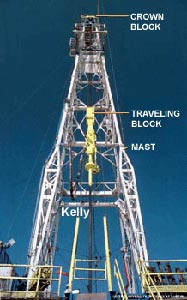

string up

v: to thread the drilling line through the sheaves of the crown block and traveling block. One end of the line is secured to the hoisting drum and the other to the drill-line anchor.

structural mast

n: a portable mast constructed of angular as opposed to tubular steel members.

stuck pipe

n: drill pipe, drill collars, casing, or tubing that has inadvertently become immovable in the hole. Sticking may occur when drilling is in progress, when casing is being run in the hole, or when the drill pipe is being hoisted.

stuck point

n: the depth in the hole at which the drill stem, tubing, or casing is stuck. Also called freeze point.

stuffing box

n: a device that prevents leakage along a piston, rod, propeller shaft, or other moving part that passes through a hole in a cylinder or vessel. It consists of a box or chamber made by enlarging the hole and a gland containing compressed packing. On a well being artificially lifted by means of a sucker rod pump, the polished rod operates through a stuffing box, preventing escape of oil and diverting it into a side outlet to which is connected the flow line leading to the oil and gas separator or to the field storage tank. For a bottomhole pressure test, the wireline goes through a stuffing box and lubricator, allowing the gauge to be raised and lowered against well pressure. The lubricator provides a pressure-tight grease seal in the stuffing box.

sub

n: a short, threaded piece of pipe used to adapt parts of the drilling string that cannot otherwise be screwed together because of differences in thread size or design. A sub (a substitute) may also perform a special function. Lifting subs are used with drill collars to provide a shoulder to fit the drill pipe elevators; a kelly saver sub is placed between the drill pipe and the kelly to prevent excessive thread wear of the kelly and drill pipe threads; a bent sub is used when drilling a directional hole.

submersible pump

n: a pump that is placed below the level of fluid in a well. It is usually driven by an electric motor and consists of a series of rotating blades that impart centrifugal motion to lift the fluid to the surface.

substructure

n: the foundation on which the derrick or mast and usually the drawworks sit; contains space for well control equipment.

sucker rod

n: a special steel pumping rod. Several rods screwed together make up the mechanical link from the beam pumping unit on the surface to the sucker rod pump at the bottom of a well. Sucker rods are threaded on each end and manufactured to dimension standards and metal specifications set by the petroleum industry. Lengths are 25 or 30 feet (7.6 or 9.1 meters); diameter varies from 1/2 to 1 1/8 inches (12 to 30 millimeters). There is also a continuous sucker rod (trade name: Corod™).

sucker rod pump

n: the downhole assembly used to lift fluid to the surface by the reciprocating action of the sucker rod string. Basic components are barrel, plunger, valves, and hold-down. Two types of sucker rod pumps are the tubing pump, in which the barrel is attached to the tubing, and the rod, or insert, pump, which is run into the well as a complete unit.

sucker rod pumping

n: a method of artificial lift in which a subsurface pump located at or near the bottom of the well and connected to a string of sucker rods is used to lift the well fluid to the surface. The weight of the rod string and fluid is counterbalanced by weights attached to a reciprocating beam or to the crank member of a beam pumping unit or by air pressure in a cylinder attached to the beam.

surface casing

n: see surface pipe.

surface hole

n: that part of the wellbore that is drilled below the conductor hole but above the intermediate hole.

surface pipe

n: the first string of casing (after the conductor pipe) that is set in a well. It varies in length from a few hundred to several thousand feet (meters).

surface stack

n: a blowout preventer stack mounted on top of the casing string at or near the surface of the ground or the water.

suspending agent

n: an additive used to hold the fine clay and silt particles that sometimes remain after an acidizing treatment in suspension; for example, it keeps them from settling out of the spent acid until it is circulated out.

swab

n. a hollow mandrel fitted with swab cups used for swabbing. v. to operate a swab on a wireline to lower the pressure in the well bore and bring well fluids to the surface when the well does not flow naturally. Swabbing is a temporary operation to determine whether the well can be made to flow. If the well does not flow after being swabbed, a pump is installed as a permanent lifting device to bring the oil to the surface.

swab cup

n: a rubber or rubberlike device on a special rod (a swab), which forms a seal between the swab and the wall of the tubing or casing.

swage

n: a solid cylindrical tool pointed at the bottom and equipped with a tool joint at the top for connection with a jar. It is used to straighten damaged or collapsed casing or tubing and drive it back to its original shape. v: to reduce the diameter of a rod, a tube, or a fitting by forging, hammering, or other method.

swamper

n: (slang) a helper on a truck, tractor, or other machine.

sweet crude oil

n: oil containing little or no sulfur, especially little or no hydrogen sulfide.

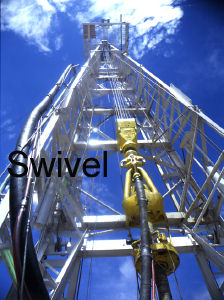

swivel

n: a rotary tool that is hung from the rotary hook and traveling block to suspend and permit free rotation of the drill stem. It also provides a connection for the rotary hose and a passageway for the flow of drilling fluid into the drill stem.