Oil and Gas Well Drilling and Servicing eTool

Oil and Gas Well Drilling and Servicing » Glossary of Terms - C

† This is an abridged version of the Dictionary of Petroleum Terms provided by Petex and the University of Texas Austin. © Petex 2001

cable

n: 1. a rope of wire, hemp, or other strong fibers. 2. braided wire used to conduct electricity, often called power cable.

caliper log

n: a record showing variations in wellbore diameter by depth, indicating undue enlargement due to caving in, washout, or other causes. The caliper log also reveals corrosion, scaling, or pitting inside tubular goods.

carrier rig

n: a specially designed, self-propelled workover or drilling rig that is driven directly to the well site. Power from a carrier rig's hoist engine or engines also propels the rig on the road. A carrier rig may be a back-in type or a drive-in type.

casing

n: 1. steel pipe placed in an oil or gas well to prevent the wall of the hole from caving in, to prevent movement of fluids from one formation to another and to aid in well control.

cased hole

n: a wellbore in which casing has been run.

casing centralizer

n: a device secured around the sing at regular intervals to center it in the hole.

casing cutter

n: a heavy cylindrical body, fitted with a set of knives, used to cut and free a section of casing in a well.

casing coupling (collar)

n: a tubular section of pipe that is threaded inside and used to connect two joints of casing.

casing crew

n: the employees of a company that specializes in preparing and running casing into a well.

casing gun

n: a perforating gun run into the casing string.

casing hanger

n: a circular device with a frictional gripping arrangement of slips and packing rings used to suspend casing from a casing head in a well.

casing head

n: a heavy, flanged steel fitting connected to the first string of casing. It provides a housing for slips and packing assemblies, allows suspension of intermediate and production strings of casing, and supplies the means for the annulus to be sealed off. Also called a casing spool.

casing point

n: the depth in a well at which casing is set, generally the depth at which the casing shoe rests.

casing pressure

n: the pressure in a well that exists between the casing and the tubing or the casing and the drill pipe.

casing spider

n: see spider.

casing slip

n: see spider.

casing string

n: the entire length of all the joints of casing run in a well.

casing shoe

n: see guide shoe.

casing tongs

n pl: large wrench used for turning when making up or breaking out casing. See tongs.

casing-tubing annulus

n: in a wellbore, the space between the inside of the casing and the outside of the tubing.

catch samples

v: to obtain cuttings for geological information as formations are penetrated by the bit. The samples are obtained from drilling fluid as it emerges from the wellbore or, in cable-tool drilling, from the bailer.

cathead

n: a spool-shaped attachment on the end of the catshaft, around which rope for hoisting and moving heavy equipment on or near the rig floor is wound. See breakout cathead, makeup cathead.

cathead clutch

n: see cathead.

cathead spool

n: see cathead.

catline boom and hoist line

n: a hoisting or pulling line powered by the cathead and used to lift heavy equipment on the rig. A structural framework erected near the top of the derrick for lifting material.

catwalk

n: 1. the elevated work area adjacent to the vdoor and ramp on a drilling rig where pipe is laid to be lifted to the derrick floor by the catline or by an air hoist. See catline. 2. any elevated walkway.

cement

n: a powder consisting of alumina, silica, lime, and other substances that hardens when mixed with water. Extensively used in the oil industry to bond casing to the walls of the wellbore.

cement bond

n: the adherence of casing to cement and cement to formation. When casing is run in a well, it is set, or bonded, to the formation by means of cement.

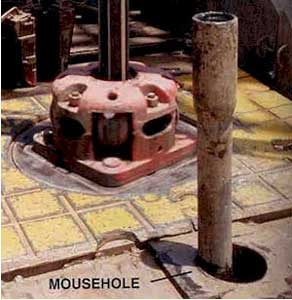

cellar

n: a pit in the ground to provide additional height between the rig floor and the well head to accommodate the installation of blowout preventers, ratholes, mouseholes, and so forth. It also may collect drainage water and other fluids for subsequent disposal.

cement bond survey

n: an acoustic survey or sonic-logging method that records the quality or hardness of the cement used in the annulus to bond the casing and the formation. Casing that is well bonded to the formation transmits an acoustic signal quickly; poorly bonded casing transmits a signal slowly. See acoustic survey, acoustic well logging.

cement casing

v: to fill the annulus between the casing and wall of the hole with cement to support the casing and prevent fluid migration between permeable zones.

cement hydration

n: reaction with water that begins when water is added to powdered cement. The cement gradually sets to a solid.

cementing

n: the application of a liquid slurry of cement and water to various points inside or outside the casing.

cementing company

n: a company whose specialty is preparing, transporting, and pumping cement into a well.

cementing head

n: an accessory attached to the top of the casing to facilitate cementing of the casing. It has passages for cement slurry and retainer chambers for cementing wiper plugs. Also called retainer head.

cementing materials

n pl: a slurry of cement and water and sometimes one or more additives that affect either the density of the mixture or its setting time. The cement used may be high early strength, common (standard), or slow setting. Additives include accelerators (such as calcium chloride), retarders (such as gypsum), weighting materials (such as barium sulfate), lightweight additives (such as bentonite), or a variety of lost circulation materials.

cement plug

n: 1. a portion of cement placed at some point in the wellbore to seal it. 2. a wiper plug. See cementing.

cementing pump

n: a high-pressure pump used to force cement down the casing and into the annular space between the casing and the wall of the borehole.

cementing time

n: the total elapsed time needed to complete a cementing operation.

cement retainer

n: a tool set temporarily in the casing or well to prevent the passage of cement, thereby forcing it to follow another designated path. It is used in squeeze cementing and other remedial cementing jobs.

centralizer

n: see casing centralizer.

centrifugal pump

n: a pump with an impeller or rotor, an impeller shaft, and a casing, which discharges fluid by centrifugal force. An electric submersible pump is a centrifugal pump.

chain tongs

n pl: a hand tool used to tighten or loosen pipe, consisting of a handle and chain that resembles the chain on a bicycle.

change house

n: a small building, or doghouse, in which members of a drilling rig or roustabout crew change clothes, store personal belongings, and so on.

channeling

n: when casing is being cemented in a borehole, the cement slurry can fail to rise uniformly between the casing and the borehole wall, leaving spaces, or channels, devoid of cement. Ideally, the cement should completely and uniformly surround the casing and form a strong bond to the borehole wall. See cement channeling.

chemical cutoff

n: a method of severing pipe in a well by applying high pressure jets of a very corrosive substance against the wall of the pipe. The resulting cut is very smooth.

chemical cutter

n: a fishing tool that uses high-pressure jets of chemicals to sever casing, tubing, or drill pipe stuck in the hole.

chemical flooding

n: a method of improved oil recovery in which chemicals dissolved in water are pumped into a reservoir through injection wells to mobilize oil left behind after primary or secondary recovery and to move it toward production wells.

choke

n: a device with an orifice installed in a line to restrict the flow of fluids. Surface chokes are part of the Christmas tree on a well and contain a choke nipple, or bean, with a small-diameter bore that serves to restrict the flow. Chokes are also used to control the rate of flow of the drilling mud out of the hole when the well is closed in with the blowout preventer and a kick is being circulated out of the hole. See choke manifold.

choke line

n: a line, or pipe, that runs from the blowout preventer stack to the choke manifold through which fluid from the hole is flowed when the well is shut in with the blowout preventer.

choke manifold

n: the arrangement of piping and special valves, called chokes, through which drilling mud is circulated when the blowout preventers are closed to control the pressures encountered during a kick.

christmas tree

n: the control valves, pressure gauges, and chokes assembled at the top of a well to control flow of oil and/or gas after the well has been drilled and completed. It is used when reservoir pressure is sufficient to cause reservoir fluids to rise to the surface.

circulate

v: to pass from one point throughout a system and back to the starting point. For example, drilling fluid is circulated out of the suction pit, down the drill pipe and drill collars, out the bit, up the annulus, and back to the pits while drilling proceeds.

circulating fluid

n: see drilling fluid, mud.

circulating head

n: an accessory attached to the top of the drill pipe or tubing to form a connection with the mud system to permit circulation of the drilling mud.

circulating pressure

n: the pressure generated by the mud pumps and exerted on the drill stem.

circulation

n: the movement of drilling fluid out of the mud pits, down the drill stem, up the annulus, and back to the mud pits. See normal circulation, reverse circulation.

circulation valve

n: an accessory employed above a packer, to permit annulus-to-tubing circulation or vice versa.

clean out

v: to remove sand, scale, and other deposits from the producing section of the well to restore or increase production.

cleanout tools

n pl: the tools or instruments, such as bailers and swabs, used to clean out an oilwell.

clutch

n: a coupling used to connect and disconnect a driving and a driven part of a mechanism, especially a coupling that permits the former part to engage the latter gradually and without shock. In the oil field, a clutch permits gradual engaging and disengaging of the equipment driven by a prime mover. v: to engage or disengage a clutch.

coiled tubing

n: a continuous string of flexible steel tubing, often hundreds or thousands of feet long, that is wound onto a reel, often dozens of feet in diameter. The reel is an integral part of the coiled tubing unit, which consists of several devices that ensure the tubing can be safely and efficiently inserted into the well from the surface. Also called reeled tubing.

coiled-tubing unit

n: the equipment for transporting and using coiled tubing, including a reel for the coiled tubing, an injector head to push the tubing down the well, a wellhead blowout preventer stack, a power source (usually a diesel engine and hydraulic pumps), and a control console. A unique feature of the unit is that it allows continuous circulation while it is being lowered into the hole. A coiled tubing unit is usually mounted on a trailer or skid.

coiled-tubing workover

n: a workover performed with a continuous steel tube, normally 0.75 inch to 1 inch (1.9 to 2.54 centimeters) outside diameter, which is run into the well in one piece inside the normal tubing. Lengths of the tubing up to 16,000 feet (4,877 meters) are stored on the surface on a reel in a manner similar to that used for wireline. The unit is rigged up over the wellhead. The tubing is injected through a control head that seals off the tubing and makes a pressure-tight connection.

collar

n: 1. a coupling device used to join two lengths of pipe, such as casing or tubing. A combination collar has left-hand threads in one end and right-hand threads in the other. 2. a drill collar.

collar locator

n: a logging device used to determine accurately the depth of a well; the log measures and records the depth of each casing collar, or coupling, in a well.

collar locator log

n: see collar locator.

come out of the hole

v: to pull the drill stem out of the wellbore to change the bit, to change from a core barrel to the bit, to run electric logs, to prepare for a drill stem test, to run casing, and so on. Also called trip out, tripping out (TOH).

company hand

n: see company representative.

company man

n: see company representative.

company representative

n: an employee of an operating company who supervises the operations at a drilling site or well site and who may coordinate the hiring of logging, testing, service, and workover companies. Also called company hand, operator's representative, or company man.

complete a well

v: to finish work on a well and bring it to productive status. See well completion.

completion fluid

n: low-solids fluid or drilling mud used when a well is being completed. It is selected not only for its ability to control formation pressure, but also for the properties that minimize formation damage.

compound

n: 1. a mechanism used to transmit power from the engines to the pump, the drawworks, and other machinery on a drilling rig. It is composed of clutches, chains and sprockets, belts and pulleys, and a number of shafts, both driven and driving. v: to connect two or more power producing devices, such as engines, to run driven equipment, such as the drawworks.

compression-ignition engine

n: a diesel engine; an engine in which the fuel/air mixture inside the engine cylinders is ignited by the heat that occurs when the fuel-air mixture is highly compressed by the engine pistons.

compressor

n: a device that raises the pressure of a compressible fluid such as air or gas. Compressors create a pressure differential to move or compress a vapor or a gas.

conductivity

n: 1. the ability to transmit or convey (as heat or electricity). 2. an electrical logging measurement obtained from an induction survey, in which eddy currents produced by an alternating magnetic field induce in a receiver coil a voltage proportionate to the ability of the formation to conduct electricity. See induction log.

conductor casing

n: generally, the first string of casing in a well. It may be lowered into a hole drilled into the formations near the surface and cemented in place; it may be driven into the ground by a special pile driver (in such cases, it is sometimes called drive pipe). Its purpose is to prevent the soft formations near the surface from caving in and to conduct drilling mud from the bottom of the hole to the surface when drilling starts. Also called conductor pipe, drive pipe.

conductor hole

n: the hole where the crew starts the top of the well.

conductor pipe

n: the largest diameter casing and the topmost length of casing. It is relatively short and encases the topmost string of casing.

cone

n: a conical-shaped metal device into which cutting teeth are formed or mounted on a roller cone bit.

connection

n: 1. a section of pipe or fitting used to join pipe to pipe or to a vessel. 2. a place in electrical circuits where wires join. 3. the action of adding a joint of pipe to the drill stem as drilling progresses.

consultant

n: a person who contracts with an oil company to supervise the operations at a drilling site or well site who may coordinate the hiring of logging, testing, service, and workover companies.

contract

n: a written agreement that can be enforced by law and that lists the terms under which the acts required are to be performed. A drilling contract may cover such factors as the cost of drilling the well (whether by the foot or by the day), the distribution of expenses between operator and contractor, and the type of equipment to be used.

core

n: a cylindrical sample taken from a formation for geological analysis.

core analysis

n: laboratory analysis of a core sample that may determine porosity, permeability, lithology, fluid content, angle of dip, geological age, and probable productivity of the formation.

core barrel

n: a tubular device, usually from 10 to 60 feet (3 to 18 meters) long, run in place of a bit and used to cut a core sample.

core sample

n: 1. a small portion of a formation obtained by using a core barrel and core bit in an existing wellbore. See core bit. 2. a spot sample of the contents of an oil or oil product storage tank usually obtained with a thief, or core sampler, at a given height in the tank.

coring

n: the process of cutting a vertical, cylindrical sample of the formations encountered as a well is drilled.

coring bit

n: a bit that does not drill out the center portion of the hole, but allows this center portion (the core) to pass through the round opening in the center of the bit and into the core barrel.

corrosion

n: any of a variety of complex chemical or electrochemical processes, such as rust, by which metal is destroyed through reaction with its environment.

corrosion inhibitor

n: a chemical substance that minimizes or prevents corrosion in metal equipment.

counterbalance weight

n: a weight applied to compensate for existing weight or force. On pumping units in oil production, counterweights are used to offset the weight of the column of sucker rods and fluid on the upstroke of the pump, and the weight of the rods on the downstroke.

coupling

n: 1. in piping, a metal collar with internal threads used to join two sections of threaded pipe. 2. in power transmission, a connection extending between a driving shaft and a driven shaft.

crane

n: a machine for raising, lowering, and revolving heavy pieces of equipment.

crane operator

n: a person who by training and experience is authorized to operate the crane and who may be in charge of the roustabout crew.

crank

n: an arm keyed at right angles to a shaft and used for changing radius of rotation or changing reciprocating motion to circular motion or circular motion to reciprocating motion. On a beam pumping unit, the crank is connected by the pitman to the walking beam, thereby changing circular motion to reciprocating motion.

crank arm

n: a steel member connected to each end of the shaft extending from each side of the speed reducer on a beam pumping unit.

crankshaft

n: a rotating shaft to which connecting rods are attached. It changes up and down (reciprocating) motion to circular (rotary) motion.

crew

n: 1. the workers on a drilling or workover rig, including the driller, the derrickhand, and the rotary helpers. 2. any group of oilfield service workers.

crooked hole

n: a wellbore that has been drilled in a direction other than vertical.

crossover sub

n: a sub that allows different sizes and types of drill pipe or other components to be joined.

crown

n: 1. the crown block or top of a derrick or mast. 2. the top of a piston. 3. a high spot formed on a tool joint shoulder as the result of wobble.

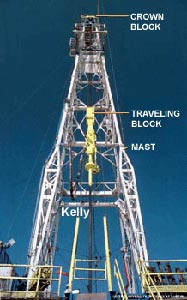

crown block and water table

n: an assembly of sheaves or pulleys mounted n beams at the top of the derrick. The drilling line is run over the sheaves down to the hoisting drum.

crown saver

n: a device mounted near the drawworks drum to keep the driller from inadvertently raising the traveling block into the crown block. A probe senses when too much line has been pulled onto the drum, indicating that the traveling block may strike the crown. The probe activates a switch that simultaneously disconnects the drawworks from its power source and engages the drawworks brake.

crude oil

n: unrefined liquid petroleum. It ranges in gravity from 9°API to 55°API and in color from yellow to black.

cutout

n: an area of deck grating removed to clear an obstruction or to permit pipes, ducts, columns, and the like to pass through the grating.

cuttings

n pl: the fragments of rock dislodged by the bit and brought to the surface in the drilling mud. Washed and dried cuttings samples are analyzed by geologists to obtain information about the formations drilled.