Oil and Gas Well Drilling and Servicing eTool

Oil and Gas Well Drilling and Servicing » Glossary of Terms - M

† This is an abridged version of the Dictionary of Petroleum Terms provided by Petex and the University of Texas Austin. © Petex 2001

macaroni string

n: a string of tubing or pipe, usually 3/4 or 1 inch (1.9 or 2.54 centimeters) in diameter.

make a connection

v: to attach a joint or stand of drill pipe onto the drill stem suspended in the wellbore to permit deepening the wellbore by the length of the pipe.

make up

v: 1. to assemble and join parts to form a complete unit (for example, to make up a string of drill pipe). 2. to screw together two threaded pieces. Compare break out. 3. to mix or prepare (for example, to make up a tank of mud). 4. to compensate for (for example, to make up for lost time).

makeup

adj: added to a system (for example, makeup water used in mixing mud).

make up a joint

v: to screw a length of pipe into another length of pipe.

makeup cathead

n: a device that is attached to the shaft of the drawworks and used as a power source for making up joints of pipe. It is usually located on the driller’s side of the drawworks. Also called spinning cathead.

makeup tongs

n pl: tongs used for screwing one length of pipe into another for making up a joint. Compare breakout tongs. See also tongs.

male connection

n: a pipe, coupling, or tool that has threads on the outside so that it can be joined to a female connection.

mandrel

n: a cylindrical bar, spindle, or shaft around which other parts are arranged or attached or that fits inside a cylinder or tube.

manifold

n: 1. an accessory system of piping to a main piping system (or another conductor) that serves to divide a flow into several parts, to combine several flows into one, or to reroute a flow to any one of several possible destinations.

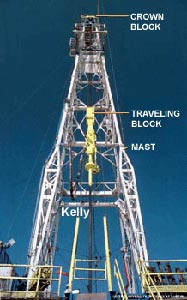

mast

n: a portable derrick that is capable of being raised as a unit, as distinguished from a standard derrick, which cannot be raised to a working position as a unit. For transporting by land, the mast can be divided into two or more sections to avoid excessive length extending from truck beds on the highway.

master bushing

n: a device that fits into the rotary table to accommodate the slips and drive the kelly bushing so that the rotating motion of the rotary table can be transmitted to the kelly.

master valve

n: 1. a large valve located on the Christmas tree and used to control the flow of oil and gas from a well. Also called master gate.

mechanical jar

n: a percussion tool operated mechanically to give an upward thrust to a fish by the sudden release of a tripping device inside the tool. If the fish can be freed by an upward blow, the mechanical jar can be very effective.

mechanical log

n: a log of, for instance, rate of penetration or amount of gas in the mud, obtained at the surface by mechanical means. See mud logging.

mechanical rig

n: a drilling rig in which the source of power is one or more internal-combustion engines and in which the power is distributed to rig components through mechanical devices (such as chains, sprockets, clutches, and shafts). Also called a power rig. Compare electric rig.

mill

n: a downhole tool with rough, sharp, extremely hard cutting surfaces for removing metal, packers, cement, sand, or scale by grinding or cutting.

miscible drive

n: a method of enhanced recovery in which various hydrocarbon solvents or gases (such as propane, LPG, natural gas, carbon dioxide, or a mixture thereof) are injected into the reservoir to reduce interfacial forces between oil and water in the pore channels and thus displace oil from the reservoir rock. See chemical flooding, gas injection.

mixing tank

n: any tank or vessel used to mix components of a substance (as in the mixing of additives with drilling mud).

mix mud

v: to prepare drilling fluids.

monitor

n: an instrument that reports the performance of a control device or signals if unusual conditions appear in a system.

monkeyboard

n: the derrickhand's working platform. As pipe or tubing is run into or out of the hole, the derrickhand must handle the top end of the pipe, which may be as high as 90 feet (27 meters) or higher in the derrick or mast.

morning report

n: see daily drilling report.

morning tour

(pronounced “tower”) n: a work shift that generally begins at or near midnight. See graveyard tour.

motorhand

n: the crew member on a rotary drilling rig, who is responsible for the care and operation of drilling engines. Also called motorman.

motor

n: any of various power units, such as a hydraulic, internal combustion, air, or electric device, that develops energy or imparts motion. Compare engine.

motorman

n: see motorhand.

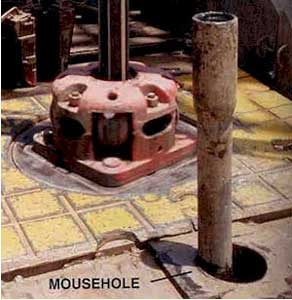

mousehole

n: shallow bores under the rig floor, usually lined with pipe, in which joints of drill pipe are temporarily suspended for later connection to the drill string.

mousehole connection

n: the procedure of adding a length of drill pipe or tubing to the active string.

mud

n: the liquid circulated through the wellbore during rotary drilling and workover operations.

mud acid

n: a mixture of hydrochloric and/or hydrofluoric acids and surfactants used to remove wall cake from the wellbore.

mud cake

n: the sheath of mud solids that forms on the wall of the hole when liquid from mud filters into the formation. Also called filter cake or wall cake.

mud centrifuge

n: a device that uses centrifugal force to separate small solid components from liquid drilling fluid.

mud cleaner

n: a cone-shaped device, a hydrocyclone, designed to remove very fine solid particles from the drilling mud.

mud engineer

n: an employee of a drilling fluid supply company whose duty it is to test and maintain the drilling mud properties that are specified by the operator.

mud-gas separator

n: a device that removes gas from the mud coming out of a well when a kick is being circulated out.

mud hopper

n: see hopper.

mud hose

n: also called kelly hose or rotary hose. See rotary hose.

mud line

n: a mud return line.

mud logging

n: the recording of information derived from examination and analysis of formation cuttings made by the bit and of mud circulated out of the hole. A portion of the mud is diverted through a gas-detecting device. Cuttings brought up by the mud are examined under ultraviolet light to detect the presence of oil or gas. Mud logging is often carried out in a portable laboratory set up at the well site.

mud motor

n: see downhole motor.

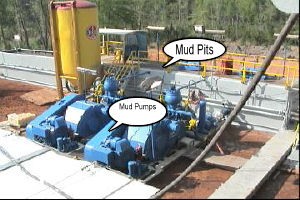

mud pit

n: originally, an open pit dug in the ground to hold drilling fluid or waste materials discarded after the treatment of drilling mud. For some drilling operations, mud pits are used for suction to the mud pumps, settling of mud sediments, and storage of reserve mud. Steel tanks are much more commonly used for these purposes now, but they are still usually referred to as pits.

mud pump

n: a large, high-pressure reciprocating pump used to circulate the mud on a drilling rig. A typical mud pump is a two or three-cylinder piston pump whose replaceable pistons travel in replaceable liners and are driven by a crankshaft actuated by an engine or a motor.

mud return line

n: a trough or pipe that is placed between the surface connections at the wellbore and the shale shaker.

mud tank

n: one of a series of open tanks, usually made of steel plate, through which the drilling mud is cycled to remove sand and fine sediments.

mud weight

n: a measure of the density of a drilling fluid expressed as pounds per gallon, pounds per cubic foot, or kilograms per cubic metre. Mud weight is directly related to the amount of pressure the column of drilling mud exerts at the bottom of the hole.

multiple completion

n: an arrangement for producing a well in which one wellbore penetrates two or more petroleum-bearing formations. In one type, multiple tubing strings are suspended side by side in the production casing string, each a different length and each packed to prevent the commingling of different reservoir fluids. Each reservoir is then produced through its own tubing string. Alternatively, a small diameter production casing string may be provided for each reservoir, as in multiple miniaturized or multiple tubingless completions. See dual completion.