Oil and Gas Well Drilling and Servicing eTool

Oil and Gas Well Drilling and Servicing » Glossary of Terms - D

† This is an abridged version of the Dictionary of Petroleum Terms provided by Petex and the University of Texas Austin. © Petex 2001

daily drilling report

n: a record made each day of the operations on a working drilling rig and, traditionally, phoned, faxed, emailed, or radioed in to the office of the drilling company and possibly the operator every morning.

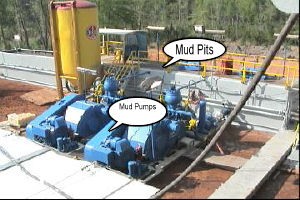

dampener

n: an air or inert gas device that minimizes pressure surges in the output line of a mud pump. Sometimes called a surge dampener.

daylight tour

(pronounced "tower") n: in areas where three eight-hour tours are worked, the shift of duty on a drilling rig that starts at or about daylight. Compare evening tour, morning (graveyard) tour.

day tour

(pronounced "tower") n: in areas where two 12-hour tours are worked, a period of 12 hours, usually during daylight, worked by a drilling or workover crew when equipment is being run around the clock.

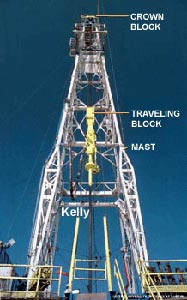

deadline

n: the drilling line from the crown block sheave to the anchor, so called because it does not move. Compare fast line.

deadline anchor

n: see deadline tie-down anchor.

deadline sheave

n: the sheave on the crown block over which the deadline is reeved.

deadline tie-down anchor

n: a device to which the deadline is attached, securely fastened to the mast or derrick substructure. Also called a deadline anchor.

deck

n: (nautical) floor.

degasser

n: the equipment used to remove unwanted gas from a liquid, especially from drilling fluid.

density

n: the mass or weight of a substance per unit volume. For instance, the density of a drilling mud may be 10 pounds per gallon, 74.8 pounds/cubic foot, or 1,198.2 kilograms/cubic meter. Specific gravity, relative density, and API gravity are other units of density.

density log

n: a special radioactivity log for open-hole surveying that responds to variations in the specific gravity of formations. It is a contact log (i.e., the logging tool is held against the wall of the hole). It emits neutrons and then measures the secondary gamma radiation that is scattered back to the detector in the instrument. The density log is an excellent porosity-measure device, especially for shaley sands. Some trade names are Formation Density Log, Gamma-Gamma Density Log, and Densilog.

derrick

n: a large load-bearing structure, usually of bolted construction. In drilling, the standard derrick has four legs standing at the corners of the substructure and reaching to the crown block. The substructure is an assembly of heavy beams used to elevate the derrick and provide space to install blowout preventers, casingheads, and so forth.

derrick floor

n: also called the rig floor.

derrickhand

n: the crew member who handles the upper end of the drill string as it is being hoisted out of or lowered into the hole. On a drilling rig, he or she may be responsible for the circulating machinery and the conditioning of the drilling or workover fluid.

derrickman

n: see derrickhand.

desander

n: a centrifugal device for removing sand from drilling fluid to prevent abrasion of the pumps. It may be operated mechanically or by a fast-moving stream of fluid inside a special cone-shaped vessel, in which case it is sometimes called a hydrocyclone.

desilter

n: a centrifugal device, similar to a desander, used to remove very fine particles, or silt, from drilling fluid to lower the amount of solids in the fluid.

diamond bit

n: a drill bit that has small industrial diamonds embedded in its cutting surface.

dies

n: a tool used to shape, form, or finish other tools or pieces of metal. For example, a threading die is used to cut threads on pipe.

die insert

n: a removable, hard-steel, serrated piece that fits into the jaws of the tongs and firmly grips the body of the drill pipe, drill collars, or casing while the tongs are making up or breaking out the pipe.

diesel-electric power

n: the power supplied to a drilling rig by diesel engines driving electric generators.

diesel engine

n: a high-compression, internal-combustion engine used extensively for powering drilling rigs. In a diesel engine, air is drawn into the cylinders and compressed to very high pressures; ignition occurs as fuel is injected into the compressed and heated air. Combustion takes place within the cylinder above the piston, and expansion of the combustion products imparts power to the piston.

diesel fuel

n: a light hydrocarbon mixture for diesel engines; it has a boiling range just above that of kerosene.

dipmeter log

n: see dipmeter survey.

dipmeter survey

n: an oilwell-surveying method that determines the direction and angle of formation dip in relation to the borehole. It records data that permit computation of both the amount and direction of formation dip relative to the axis of the hole and thus provides information about the geologic structure of the formation. Also called dipmeter log or dip log.

directional drilling

n: 1. intentional deviation of a wellbore from the vertical. Although wellbores are normally drilled vertically, it is sometimes necessary or advantageous to drill at an angle from the vertical. Controlled directional drilling makes it possible to reach subsurface areas laterally remote from the point where the bit enters the earth.

directional hole

n: a wellbore intentionally drilled at an angle from the vertical. See directional drilling.

displacement fluid

n: in well cementing, the fluid, usually drilling mud or salt water, that is pumped into the well after the cement is pumped into it to force the cement out of the casing and into the annulus.

dissolved gas

n: natural gas that is in solution with crude oil in the reservoir.

dissolved-gas drive

n: a source of natural reservoir energy in which the dissolved gas coming out of the oil expands to force the oil into the wellbore. Also called solution-gas drive. See reservoir drive mechanism.

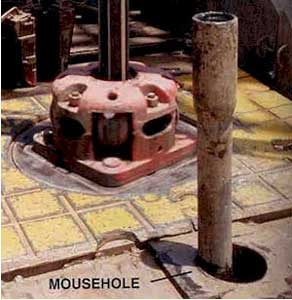

doghouse

n: a small enclosure on the rig floor used as an office and/or as a storehouse for small objects. Also, any small building used as an office or for storage.

dogleg

n: 1. an abrupt change in direction in the wellbore, frequently resulting in the formation of a keyseat. 2. a sharp bend permanently put in an object such as a pipe, wire rope, or a wire rope sling.

double

n: a length of drill pipe, casing, or tubing consisting of two joints screwed together.

downhole

adj, adv: pertaining to the wellbore.

downhole motor

n: a drilling tool made up in the drill string directly above the bit. It causes the bit to turn while the drill string remains fixed. It is used most often as a deflection tool in directional drilling, where it is made up between the bit and a bent sub (or, sometimes, the housing of the motor itself is bent). Two principal types of downhole motor are the positive-displacement motor and the downhole turbine motor.

drawworks

n: the hoisting mechanism on a drilling rig. It is essentially a large winch that spools off or takes in the drilling line and thus lowers or raises the drill stem and bit.

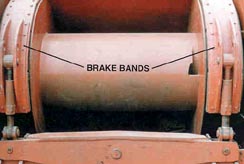

drawworks brake

n: the mechanical brake on the drawworks that can slow or prevent the drawworks drum from moving.

drawworks drum

n: the spool-shaped cylinder in the drawworks around which drilling line is wound or spooled.

drill

v: to bore a hole in the earth, usually to find and remove subsurface formation fluids such as oil and gas.

drillable

adj: pertaining to packers and other tools left in the wellbore to be broken up later by the drill bit. Drillable equipment is made of cast iron, aluminum, plastic, or other soft, brittle material.

drillable packer

n: a permanent packer that can only be removed by drilling it out.

drill ahead

v: to continue drilling operations.

drill bit

n: the cutting or boring element used in drilling oil and gas wells. Most bits used in rotary drilling are roller-cone bits. The bit consists of the cutting elements and the circulating element. The circulating element permits the passage of drilling fluid and utilizes the hydraulic force of the fluid stream to improve drilling rates.

drill collars

n: a heavy, thick-walled tube, usually steel, used between the drill pipe and the bit in the drill stem, used to stiffen the drilling assembly an put weight on the bit so that the bit can drill.

drill collar sub

n: a sub made up between the drill string and the drill collars that is used to ensure that the drill pipe and the collar can be joined properly.

driller

n: the employee normally in charge of a specific (tour) drilling or workover crew. The driller’s main duty is operation of the drilling and hoisting equipment, but this person may also be responsible for downhole condition of the well, operation of downhole tools, and pipe measurements.

driller’s position

n: the area immediately surrounding the driller’s console.

drill floor

n: also called rig floor or derrick floor. See rig floor.

drill in

v: to penetrate the productive formation after the casing is set and cemented on top of the pay zone.

drilling contract

n: an agreement made between a drilling company and an operating company to drill a well. It generally sets forth the obligation of each party, compensation, identification, method of drilling, depth to be drilled, and so on.

drilling crew

n: a driller, a derrickhand, and two or more helpers who operate a drilling or workover rig for one tour each day.

drilling engine

n: an internal-combustion engine used to power a drilling rig. These engines are used on a rotary rig and are usually fueled by diesel fuel, although liquefied petroleum gas, natural gas, and, very rarely, gasoline can also be used.

drilling engineer

n: an engineer who specializes in the technical aspects of drilling.

drilling fluid

n: circulating fluid, one function of which is to lift cuttings out of the wellbore and to the surface. It also serves to cool the bit and to counteract downhole formation pressure.

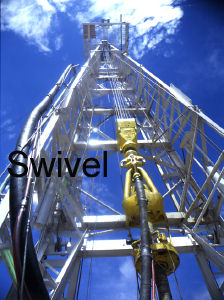

drilling hook

n: the large hook mounted on the bottom of the traveling block and from which the swivel is suspended.

drilling mud

n: a specially compounded liquid circulated through the wellbore during rotary drilling operations. See drilling fluid, mud.

drill pipe

n: the heavy seamless tubing used to rotate the bit and circulate the drilling fluid. Joints of pipe are generally approximately 30 feet long are coupled together by means of tool joints.

drill stem

n: all members in the assembly used for rotary drilling from the swivel to the bit, including the kelly, the drill pipe and tool joints, the drill collars, the stabilizers, and various specialty items. Compare drill string.

drill stem test (DST)

n: a method of formation testing. The basic drill stem test tool consists of a packer or packers, valves or ports that may be opened and closed from the surface, and two or more pressure-recording devices. The tool is lowered on the drill string to the zone to be tested. The packer or packers are set to isolate the zone from the drilling fluid column.

driller's console

n: the control panel, where the driller controls drilling operations.

drilling line

n: a wire rope hoisting line, reeved on sheaves of the crown block and traveling block (in effect a block and tackle), the primary purpose of which is to hoist or lower drill pipe or casing from or into a well.

drilling out

n: the operation during the drilling procedure when the cement is drilled out of the casing.

drill string

n: the column, or string, of drill pipe with attached tool joints that transmits fluid and rotational power from the kelly to the drill collars and the bit. Often, the term is loosely applied to include both drill pipe and drill collars.

drive bushing

n: see kelly bushing.

drive chain

n: a chain by means of which a machine is propelled.

drive-in unit

n: a type of portable service or workover rig that is self-propelled, using power from the hoisting engines. The driver's cab and steering wheel are mounted on the same end as the mast support; thus the unit can be driven straight ahead to reach the wellhead.

drive pipe

n: see conductor casing.

drum (rope)

n: a rotating cylinder with side flanges on which wire or other rope used in machine operation is wrapped.

dry hole

n: any well that does not produce oil or gas in commercial quantities. A dry hole may flow water, gas, or even oil, but not in amounts large enough to justify production.

dual completion

n: a single well that produces from two separate formations at the same time. Production from each zone is segregated by running two tubing strings with packers inside the single string of production casing, or by running one tubing string with a packer through one zone while the other is produced through the annulus. In a miniaturized dual completion, two separate casing strings are run and cemented in the same wellbore.

dump bailer

n: a bailing device with a release valve, usually of the disk or flapper type, used to place, or spot, material (such as cement slurry) at the bottom of the well.