Oil and Gas Well Drilling and Servicing eTool

Oil and Gas Well Drilling and Servicing » Glossary of Terms - R

† This is an abridged version of the Dictionary of Petroleum Terms provided by Petex and the University of Texas Austin. © Petex 2001

rack

n: 1. framework for supporting or containing a number of loose objects, such as pipe. See pipe rack. 2. a bar with teeth on one face for gearing with a pinion or worm gear. 3. a notched bar used as a ratchet. v: 1. to place on a rack. 2. to use as a rack.

radiation logging

n: see radioactivity well logging.

radioactivity log

n: a record of the natural or induced radioactive characteristics of subsurface formations. Also called nuclear log. See radioactivity well logging.

radioactivity well logging

n: the recording of the natural or induced radioactive characteristics of subsurface formations. A radioactivity log, also known as a radiation log or a nuclear log, normally consists of two recorded curves: a gamma ray curve and a neutron curve. Both help to determine the types of rocks in the formation and the types of fluids contained in the rocks.

ram

n: the closing and sealing component on a blowout preventer. One of three types—blind, pipe, or shear—may be installed in several preventers mounted in a stack on top of the wellbore. Blind rams, when closed, form a seal on a hole that has no drill pipe in it; pipe rams, when closed, seal around the pipe; shear rams cut through drill pipe and then form a seal.

ram blowout preventer

n: a blowout preventer that uses rams to seal off pressure on a hole that is with or without pipe. It is also called a ram preventer. Ram-type preventers have interchangeable ram blocks to accommodate different O.D. drill pipe, casing, or tubing.

range of load

n: in sucker rod pumping, the difference between the polished rod peak load on the upstroke and the minimum load on the downstroke.

rate of penetration (ROP)

n: a measure of the speed at which the bit drills into formations, usually expressed in feet (meters) per hour or minutes per foot (meter).

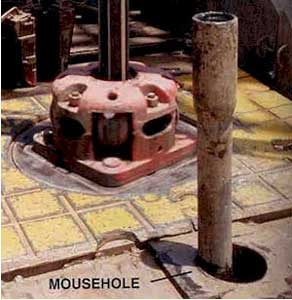

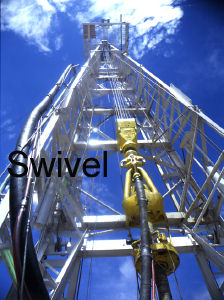

rathole

n: 1. a hole in the rig floor, some 30 to 40 feet (9 to 12 meters) deep, which is lined with casing that projects above the floor, into which the kelly and the swivel are placed when hoisting operations are in progress. 2. a hole of a diameter smaller than the main hole and drilled in the bottom of the main hole. v: to reduce the size of the wellbore and drill ahead.

rathole connection

n: the addition of a length of drill pipe or tubing to the active string using the rathole instead of the mousehole, which is the more common connection. Compare mousehole connection.

rathole rig

n: a small, usually truck-mounted rig, the purpose of which is to drill ratholes for regular drilling rigs that will be moved in later. A rathole rig may also drill the top part of the hole, the conductor hole, before the main rig arrives on location.

ream

v: to enlarge the wellbore by drilling it again with a special bit.

reamer

n: a tool used in drilling to smooth the wall of a well, enlarge the hole to the specified size, help stabilize the bit, straighten the wellbore if kinks or doglegs are encountered, and drill directionally.

reciprocating motion

n: back-and-forth or up-and-down movement, such as that of a piston in a cylinder.

reciprocating pump

n: a pump consisting of a piston that moves back and forth or up and down in a cylinder. The cylinder is equipped with inlet (suction) and outlet (discharge) valves. On the intake stroke, the suction valves are opened, and fluid is drawn into the cylinder. On the discharge stroke, the suction valves close, the discharge valves open, and fluid is forced out of the cylinder.

recompletion

n: after the initial completion of a well, the action and techniques of reentering the well and redoing or repairing the original completion to restore the well’s productivity.

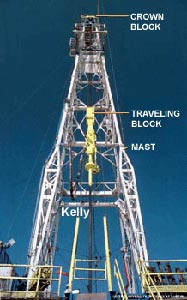

reeve (the line)

v: to string a wire rope drilling line through the sheaves of the traveling and crown blocks to the hoisting drum.

refracturing

n: fracturing a formation again.

remote BOP control panel

n: a device placed on the rig floor that can be operated by the driller to direct air pressure to actuating cylinders that turn the control valves on the main BOP control unit, located a safe distance from the rig.

remote choke panel

n: a set of controls, usually placed on the rig floor, or elsewhere on location, that is manipulated to control the amount of drilling fluid being circulated through the choke manifold. This procedure is necessary when a kick is being circulated out of a well. See choke manifold.

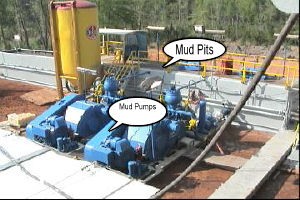

reserve pit

n: 1. (obsolete) a mud pit in which a supply of drilling fluid is stored.

reserves

n pl: the unproduced but recoverable oil or gas in a formation that has been proved by production.

reserve tank

n: a special mud tank that holds mud that is not being actively circulated. A reserve tank usually contains a different type of mud from that which the pump is currently circulating. For example, it may store heavy mud for emergency well-control operations.

reservoir

n: a subsurface, porous, permeable or naturally fractured rock body in which oil or gas are stored. Most reservoir rocks are limestones, dolomites, sandstones, or a combination of these. The four basic types of hydrocarbon reservoirs are oil, volatile oil, dry gas, and gas condensate. An oil reservoir generally contains three fluids—gas, oil, and water—with oil the dominant product. In the typical oil reservoir, these fluids become vertically segregated because of their different densities. Gas, the lightest, occupies the upper part of the reservoir rocks; water, the lower part; and oil, the intermediate section. In addition to its occurrence as a cap or in solution, gas may accumulate independently of the oil; if so, the reservoir is called a gas reservoir. Associated with the gas, in most instances, are salt water and some oil. Volatile oil reservoirs are exceptional in that during early production they are mostly productive of light oil plus gas, but, as depletion occurs, production can become almost totally completely gas. Volatile oils are usually good candidates for pressure maintenance, which can result in increased reserves. In the typical dry gas reservoir natural gas exists only as a gas and production is only gas plus fresh water that condenses from the flow stream reservoir. In a gas condensate reservoir, the hydrocarbons may exist as a gas, but, when brought to the surface, some of the heavier hydrocarbons condense and become a liquid.

reservoir drive

n: see reservoir drive mechanism.

reservoir drive mechanism

n: the process in which reservoir fluids are caused to flow out of the reservoir rock and into a wellbore by natural energy. Gas drive depends on the fact that, as the reservoir is produced, pressure is reduced, allowing the gas to expand and provide the principal driving energy. Water drive reservoirs depend on water and rock expansion to force the hydrocarbons out of the reservoir and into the wellbore. Also called natural drive energy.

reservoir oil

n: oil in place in the reservoir; retained in a reservoir as residual gas saturation is an inverse function of the pressure, due to the physics of gas.

reservoir pressure

n: the average pressure within the reservoir at any given time. Determination of this value is best made by bottomhole pressure measurements with adequate shut-in time. If a shut-in period long enough for the reservoir pressure to stabilize is impractical, then various techniques of analysis by pressure buildup or drawdown tests are available to determine static reservoir pressure.

reservoir rock

n: a permeable rock that may contain oil or gas in appreciable quantity and through which petroleum may migrate.

resistivity

n: the electrical resistance offered to the passage of current; the opposite of conductivity.

resistivity log

n: a record of the resistivity of a formation. Usually obtained when an electric log is run. See resistivity well logging.

resistivity well logging

n: the recording of the resistance of formation water to natural or induced electrical current. The mineral content of subsurface water allows it to conduct electricity. Rock, oil, and gas are poor conductors. Resistivity measurements can be correlated to formation lithology, porosity, permeability, and saturation and are very useful in formation evaluation.

retrievable packer

n: a packer that can be pulled out of the well to be repaired or replaced.

reverse circulation

n: the course of drilling fluid downward through the annulus and upward through the drill stem, in contrast to normal circulation in which the course is downward through the drill stem and upward through the annulus. Seldom used in open hole, but frequently used in workover operations.

rework

v: to restore production from an existing formation when it has fallen off substantially or ceased altogether.

rig

n: the derrick or mast, drawworks, and attendant surface equipment of a drilling or workover unit.

rig down

v: to dismantle a drilling rig and auxiliary equipment following the completion of drilling operations. Also called tear down.

rig floor

n: the area immediately around the rotary table and extending to each corner of the derrick or mast—that is, the area immediately above the substructure on which the rotary table, and so forth rest.

rig up

v: to prepare the drilling rig for making hole, for example, to install tools and machinery before drilling is started.

rod blowout preventer

n: a ram device used to close the annular space around the polished rod or sucker rod in a pumping well.

rod hanger

n: a device used to hang sucker rods on the mast or in the derrick.

rod pump

n: see sucker rod pump.

rod string

n: a sucker rod string, that is, the entire length of sucker rods, which usually consists of several single rods screwed together. The rod string serves as a mechanical link from the beam pumping unit on the surface to the sucker rod pump near the bottom of the well.

roller chain

n: a type of chain that is used to transmit power by fitting over sprockets attached to shafts, causing rotation of one shaft by the rotation of another. Transmission roller chain consists of offset links, pin links, and roller links.

rotary

n: the machine used to impart rotational power to the drill stem while permitting vertical movement of the pipe for rotary drilling. Modern rotary machines have a special component, the rotary or master bushing, to turn the kelly bushing, which permits vertical movement of the kelly while the stem is turning.

rotary bushing

n: see master bushing.

rotary drilling

n: a drilling method in which a hole is drilled by a rotating bit to which a downward force is applied. The bit is fastened to and rotated by the drill stem, which also provides a passageway through which the drilling fluid is circulated. Additional joints of drill pipe are added as drilling progresses.

rotary helper

n: a worker on a drilling or workover rig, subordinate to the driller, whose primary work station is on the rig floor. Sometimes called floorhand, floorman, rig crew member, or roughneck.

rotary hose

n: the hose on a rotary drilling rig that conducts the drilling fluid from the mud pump and standpipe to the swivel and kelly; also called the mud hose or the kelly hose. It is a steel-reinforced, flexible hose that is installed between the standpipe and the swivel or top drive.

rotary shoe

n: a length of pipe whose bottom edge is serrated or dressed with a hard cutting material and that is run into the wellbore around the outside of stuck casing, pipe, or tubing to mill away the obstruction.

rotary speed

n: the speed, measured in revolutions per minute, at which the rotary table is operated.

rotary support table

n: a strong but relatively lightweight device used on some rigs that employ a top drive to rotate the bit. Although a conventional rotary table is not required to rotate the bit on such rigs, crew members must still have a place to set the slips to suspend the drill string in the hole when tripping or making a connection. A rotary support table provides such a place but does not include all the rotary machinery required in a regular rotary table.

rotary table

n: The principal component of a rotary, or rotary machine, used to turn the drill stem and support the drilling assembly. It has a beveled gear arrangement to create the rotational motion and an opening into which bushings are fitted to drive and support the drilling assembly.

roughneck

n: see rotary helper.

round trip

n: the procedure of pulling out and subsequently running back into the hole a string of drill pipe or tubing. Also called tripping.

run casing

v: to lower a string of casing into the hole. Also called to run pipe.

run in

v: to go into the hole with tubing, drill pipe, and so forth.

run pipe

v: to lower a string of casing into the hole. Also called to run casing.