Oil and Gas Well Drilling and Servicing eTool

Oil and Gas Well Drilling and Servicing » Glossary of Terms - T

† This is an abridged version of the Dictionary of Petroleum Terms provided by Petex and the University of Texas Austin. © Petex 2001

tally

v: to measure and record the total length of pipe, casing, or tubing that is to be run in a well.

taper tap

n: a tap with a gradually decreasing diameter from the top. It is used to retrieve a hollow fish such as a drill collar and is the male counterpart of a die collar. The taper tap is run into a hollow fish and rotated to cut enough threads to provide a firm grip and permit the fish to be pulled and recovered.

tapered bowl

n: a fitting, usually divided into two halves, that crew members place inside the master bushing to hold the slips.

TD

abbr: total depth.

tag

v: to touch an object downhole with the drill stem.

tag line

n: in crane and truck operations, a rope attached to the bottom of a load suspended by the crane or truck, which, when grasped by a crew member, allows the crew member to prevent rotation and to assist in guiding the load.

tear down

v: see rig down.

telescoping mast

n: a portable mast that can be erected as a unit, usually by a tackle that hoists the wireline or by a hydraulic ram. The upper section of a telescoping mast is generally nested (telescoped) inside the lower section of the structure and raised to full height either by the wireline or by a hydraulic system.

temperature log

n: a survey run in cased holes to locate the top of the cement in the annulus. Since cement generates a considerable amount of heat when setting, a temperature increase will be found at the level where cement is found behind the casing.

temperature survey

n: an operation used to determine temperatures at various depths in the wellbore. It is also used to determine the height of cement behind the casing and to locate the source of water influx into the wellbore.

tertiary recovery

n: 1. the use of improved recovery methods that not only restore formation pressure but also improve oil displacement or fluid flow in the reservoir. 2. the use of any improved recovery method to remove additional oil after secondary recovery. Compare primary recovery, secondary recovery.

thermal recovery

n: a type of improved recovery in which heat is introduced into a reservoir to lower the viscosity of heavy oils and to facilitate their flow into producing wells. The pay zone may be heated by injecting steam (steam drive) or by injecting air and burning a portion of the oil in place (in situ combustion).

throw the chain

v: to jump the spinning chain up from a box end tool joint so that the chain wraps around the pin end tool joint after it is stabbed into the box. The stand or joint of drill pipe is turned or spun by a pull on the spinning chain from the cathead on the drawworks.

tight formation

n: a petroleum- or water-bearing formation of relatively low porosity and permeability.

tight sand

n: sand or sandstone formation with low permeability.

tight spot

n: a section of a borehole in which excessive wall cake has built up, reducing the hole diameter and making it difficult to run the tools in and out. Compare keyseat.

tongs

n pl: the large wrenches used for turning when making up or breaking out drill pipe, casing, tubing, or other pipe; variously called casing tongs, rotary tongs, and so forth according to the specific use. Power tongs or power wrenches are pneumatically or hydraulically operated tools that serve to spin the pipe up and, in some instances, to apply the final makeup torque.

toolpusher

n: an employee of a drilling contractor who is in charge of the entire drilling crew and the drilling rig. Also called a rig superintendent, drilling foreman, or rig supervisor.

top drive

n: a device similar to a power swivel that is used in place of the rotary table to turn the drill stem.

top plug

n: a cement wiper plug that follows cement slurry down the casing. It goes before the drilling mud used to displace the cement from the casing and separates the mud from the slurry. See cementing, wiper plug.

torque

n: the turning force that is applied to a shaft or other rotary mechanism to cause it to rotate or tend to do so. Torque is measured in foot-pounds, joules, newton-metres, and so forth.

total depth (TD)

n: the maximum depth reached in a well.

tour

(pronounced "tower") n: a working shift for drilling crew or other oilfield workers. Some tours are 8 hours; the three daily tours are called daylight, evening (or afternoon), and graveyard (or morning). 12-hour tours may also be used; they are called simply day tour and night tour.

tourly

(pronounced "towerly") adv: during each shift. See tour.

tracer

n: a substance added to reservoir fluids to permit the movements of the fluid to be followed or traced. Dyes and radioactive substances are used as tracers in underground water flows and sometimes helium is used in gas. When samples of the water or gas taken some distance from the point of injection reveal signs of the tracer, the route of the fluids can be mapped.

tracer log

n: a survey that uses a radioactive tracer such as a gas, liquid, or solid having a high gamma ray emission. When the material is injected into any portion of the wellbore, the point of placement or movement can be recorded by a gamma ray instrument. The tracer log is used to determine channeling or the travel of squeezed cement behind a section of perforated casing.

trailer rig

n: a rig mounted on a wheeled and towed trailer. It has a mast, a rotary, and one or two engines.

transmission

n: the gear or chain arrangement by which power is transmitted from the prime mover to the drawworks, the mud pump, or the rotary table of a drilling rig.

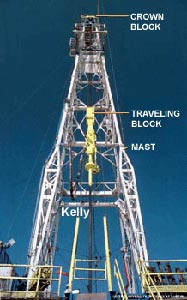

traveling block

n: an arrangement of pulleys, or sheaves, through which drilling cable is reeved, which moves up or down in the derrick or mast.

traveling valve

n: one of the two valves in a sucker rod pumping system. It moves with the movement of the sucker rod string. On the upstroke, the ball member of the valve is seated, supporting the fluid load. On the downstroke, the ball is unseated, allowing fluid to enter into the production column. Compare standing valve.

trip

n: the operation of hoisting the drill stem from and returning it to the wellbore. v: to insert or remove the drill stem into or out of the hole. Shortened form of "make a trip."

trip in

v: to go in the hole.

trip out

v: to come out of the hole.

tripping

n: the operation of hoisting the drill stem out of and returning it into the wellbore.

truck-mounted rig

n: a well-servicing and workover rig that is mounted on a truck chassis.

tubing

n: relatively small-diameter pipe that is run into a well to serve as a conduit for the passage of oil and gas to the surface.

tubing coupling

n: a special connector used to connect lengths of tubing.

tubing hanger

n: an arrangement of slips and packing rings used to suspend tubing from the tubing head.

tubing head

n: a flanged fitting that supports the tubing string, seals off pressure between the casing and the outside of the tubing, and provides a connection that supports the Christmas tree.

tubing pump

n: a sucker rod pump in which the barrel is attached to the tubing. See sucker rod pump.

tubular goods

n pl: any kind of pipe. Oilfield tubular goods include tubing, casing, drill pipe, drill collars and line pipe. Also called tubulars.

tungsten carbide

n: a fine, very hard, gray crystalline powder, a compound of tungsten and carbon. This compound is bonded with cobalt or nickel in cemented carbide compositions and used for cutting tools, abrasives, and dies.

tungsten carbide bit

n: a type of roller cone bit with inserts made of tungsten carbide. Also called tungsten carbide insert bit.

turntable

n: see rotary table.